Hydraulic robots will usher in a new era of development

In the field of robots, the most common driving system is electric drive, but because the output power of electric drive is relatively small and transmission components such as gear reducer are easy to wear, so in some high-power applications, robots generally use hydraulic drive system. Compared with electric drive, hydraulic drive has more advantages in output power, broadband, responsiveness and accuracy.

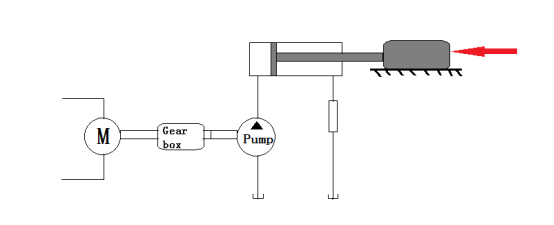

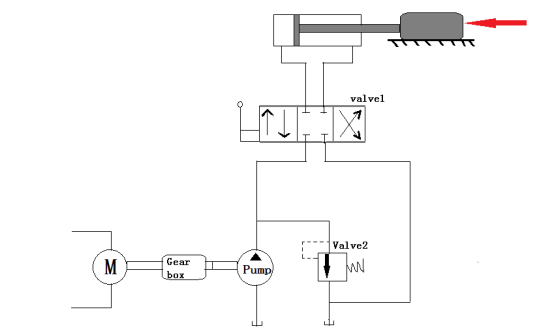

Hydraulic system

In recent years, with the vigorous development of economy, hydraulic robots have become one of the most important roles in the field of robots, but the traditional hydraulic technology has been unable to meet the market demand. With the development of hydraulic technology and control technology, various new types of hydraulic control robots are emerging one by one.

1. Tokyo University of Technology: New Hydraulic Actuator

According to foreign media, researchers at Tokyo University of Technology have recently developed a hydraulic actuator that allows robust robots to operate in disaster sites and other harsh environments.

Most of the mainstream hydraulic actuators on the market still revolve around industrial machinery, such as shovels that are too big and too heavy to be used in robots, let alone the balance and movement capabilities required by robots.

Compared with traditional motors, the hydraulic actuator developed by researchers at Tokyo University of Technology has greater power, higher impact resistance, smaller size, higher output and more stable control. It can make the robot run in the worst environment and work hard with soft touch.

Compared with the popular hydraulic actuators on the market, they are smaller in size and smoother in sliding. Through the low friction seal and innovative design, the traditional hydraulic robots can not move accurately and the robot's force control can be perfectly solved.

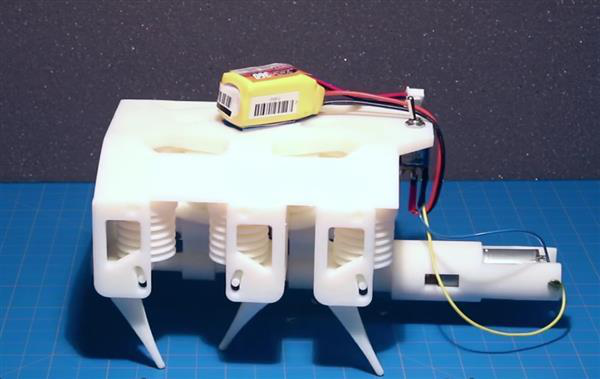

2. MIT CSAIL Laboratory: 3D Printing Integrated Hydraulic Robot

A 3-D printer robot, a 3-D printing integrated hydraulic robot made of solid and liquid materials, has been released by an academic report platform.

The robot is a hydraulic and dynamic structure of MIT CSAIL Laboratory. The material is deposited into different parts by selective light curing equipment, and then the material around the UV light curing liquid is used.

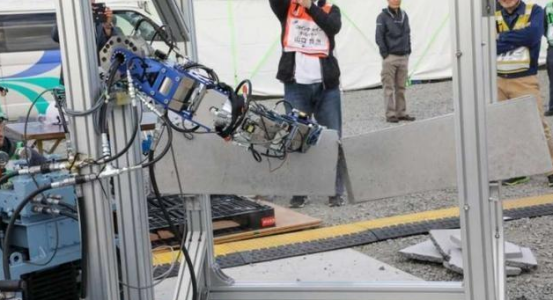

3. Swedish Brook Company: Brokk Hydraulic Hammer Robot

Brokk Hydraulic Hammer Robot is a multi-performance robot developed by Brook Company in Sweden. It has three-arm structure, which can realize the multi-direction crushing operation of hydraulic hammer. The design of electric power remote control control greatly reduces the volume and weight of the robot, improves the safety and efficiency of crushing operation, and makes it possible to replace manual crushing hammer operation.

At present, Brokk robots have been widely used in metallurgical, cement and building reconstruction industries in China. With the rapid development of economy, the requirement of tunnel construction is getting higher and higher. Brokk demolition robot will play an increasingly important role in tunnel construction because of its flexible, environmentally friendly and efficient characteristics.

It is undeniable that although there are still many problems and puzzles in hydraulic robots, hydraulic technology is gradually improving. With the increasing role of hydraulic technology in the national economy, hydraulic technology can only meet the changing market demand by striding in the direction of high efficiency, high precision and high performance.